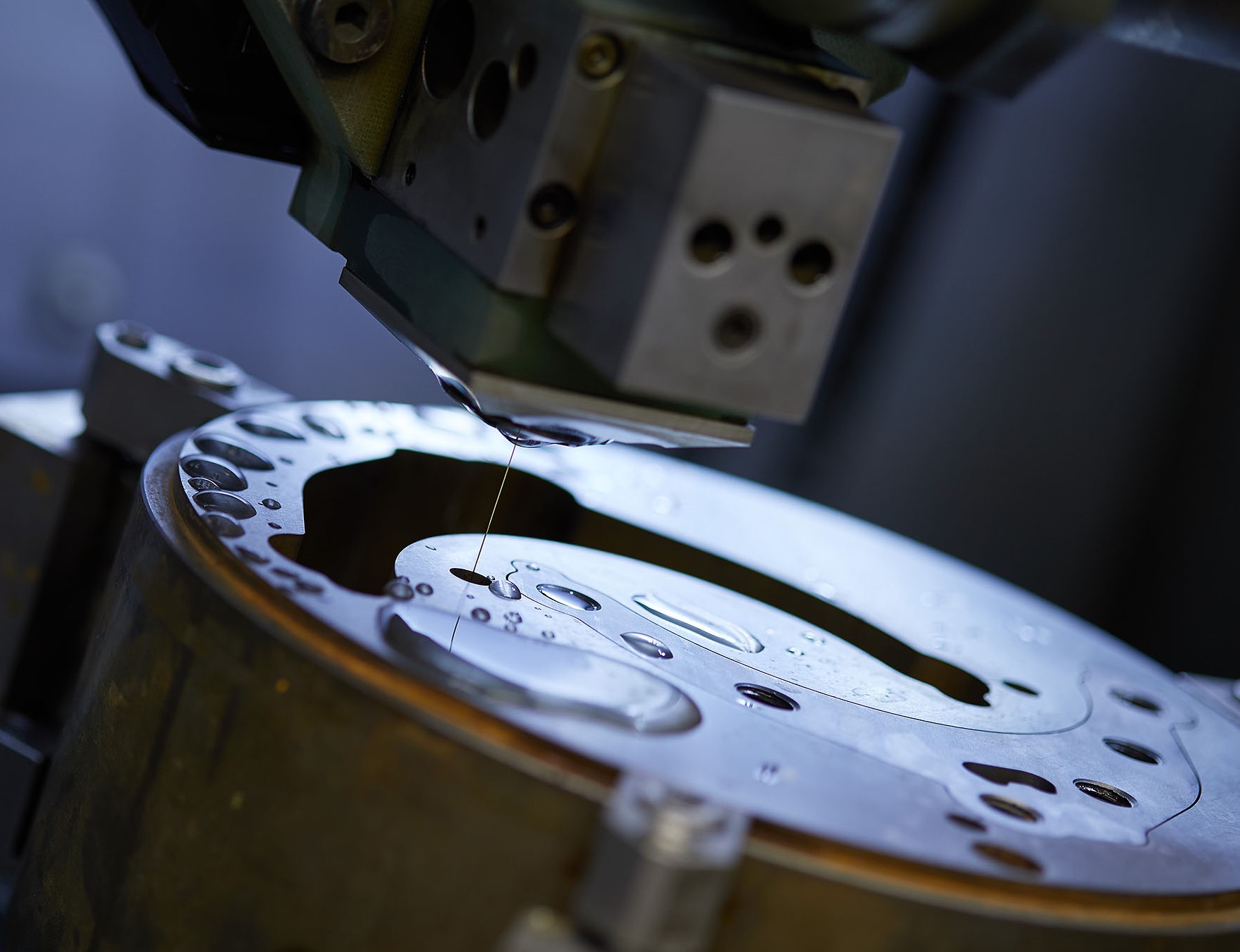

The interaction between our state-of-the-art machinery and our high-performing employees results in powerful and efficient manufacturing down the line. Great flexibility and persuasive quality are essential preconditions for quickly executing your orders.

Please contact us and learn more about our performance. We look forward to meeting you.